PassMark USB Power Delivery Tester FAQ

Can I run multiple testers at the same time on one PC?

- Yes, you can run multiple testers on one PC. You'll need a USB port per unit. For each unit connected you need to run a separate instance of the software.

Is there a protocol analyzer in the PC software?

- Yes, for the PM125 model only, the PC software can record and display all power delivery messages sent and read by the tester.

Can the unit dissipate 100W continuously?

- Continuous 100W power dissipation is right at the limit of the fans and heat sink to dump the heat without internal overheating. To be sure it will work, the tester needs to be in cool environment (e.g. 21C) and have some additional airflow across the unit. The unit will auto-shut down if the heat sink temperature reaches 75C, or the internal MOSFET junction temperature reaches 150C. 60W continuous should be possible is nearly all environments.

Is PD3.0 supported?

- Yes, we support USB Power Delivery 3.0 for fixed power profile selection.

Does the tester support Programmable Power Supply (PPS)?

- Programmable Power Supply (PPS) is one of additions to the USB-C Power Delivery 3.0 standard. A power supply’s output voltage can be programmatically adjusted in small increments (20mv) over its advertised range. PPS is supported in the PM125 model.

Does the tester support Quick Charge (QC)?

- Quick Charge is a Qualcomm’s proprietary technology which allows for the charging of battery powered devices at levels above and beyond the typical 5 volts and 2 amps. QC1, QC2, QC3, QC4 and QC4+ are supported in the PM125 model.

Is there a Linux driver for the device?

- Not at this time. But see the details about the API below. The device can also be used stand alone without any connection to a PC.

Is there an SDK / API to use the device from my own software?

- Yes. There is a protocol guide showing the commands required to control the to the device and example soure code (in C++ on Windows). See the USB PD Download page for details.

Does the device need to be connected to a PC?

- No. You can use the device in a standalone manner. A standard 5V USB power supply is required however, additional functionality such as graphing is available in the PC software however.

How many power profiles can be displayed / selected?

- A maximum of 7 profiles (depending on what the device under test supports)

Where can I get firmware updates?

- Firmware updates are available on the download page.

The USBPDTest Software detects my device but can not connect?

- This issue can occur if the firmware version installed is older than V2.4, as this is not compatible with the latest versions of the software and so a firmware update is required to use them. To update the device, you must first update to V2.4, and then after that use the latest firmware updater tool to update it to the most recent firmware version. You can download the V2.4 firmware updater tool by clicking here.

What voltages are supported?

- Any voltage between 5V to 20V can be used (depending on what power profiles the device under test supports).

Can I force an overcurrent situation?

- Yes, from the PC software you can override the limit advertised by the device. This can simulate a badly behaved / faulty USB device. This can be useful if you are an electrical engineer designing a charging device and need to test the safety of the USB charger. WARNING: While the expected behaviour of USB chargers is to shut down in an over current situation, this might not happen. The consequences of which might be a catastrophic failure of the device under test. Including smoke, fire, short circuits and electrocution hazards.

I get an error message "Rotate Connector" what does this mean?

- In theory, the USB Type-C connector is reversible, but the older USB3 port (use for the downstream loopback port link) is not reversible. There is a supporting logic in the USB PD tester to identify whether the Type-C cable is flipped or not. When the loopback port is enabled, the tester will identify the orientation but needs a multiplexer to forward the active USB3 lines to the Loopback port. The tester lacks such a switch, and therefore the cable should be manually flipped from the device side. This will allow the type-c data lines to connect to the USB3 data lines. The reason we didn’t include this switch was that it degrades the signal integrity (switch itself and the extra two ESD protection chips) and also makes our device more susceptible to ESD shocks. Note that this Rotate Connector message only appears when the "Loopback Port" option is enabled, so if you don’t have a device connected to the loopback port, you can disable the "Loopback Port" and as result the tester won’t be sensitive to the orientation.

How can I measure the capacity of USB power banks?

-

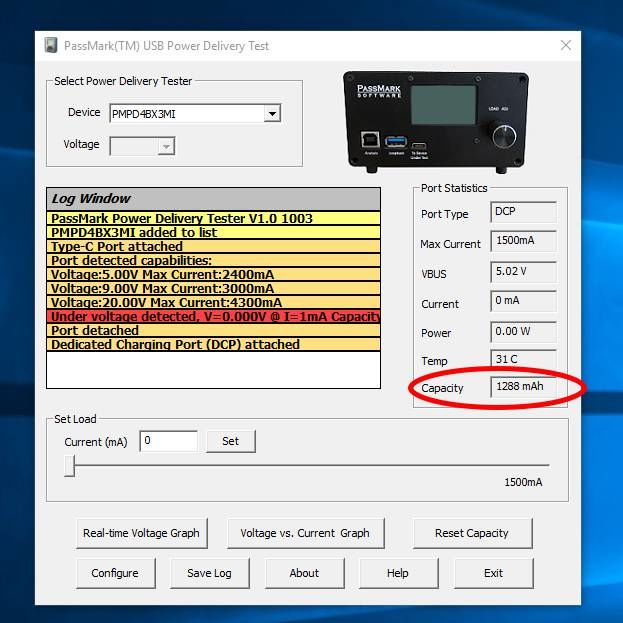

To measure the capacity of a USB power bank or battery pack, first make sure that the battery is fully charged. With the USB Power Delivery Tester switched on and connected to a monitoring machine with the monitoring software running, first click the "Reset Capacity" button in the user interface. Then, connect the power bank to the USB Power Delivery Tester. Then, set the current to a value that fairly demonstrates the power bank's capabilities (e.g. 1000mA or 1500mA). The current can be set precisely using the USBPD Test software user interface. Note that it is not necessary to set the current to the maximum advertised current as higher currents can result in more heat dissipation which will reduce the efficiency of the power bank's output. Then, leave the device running until the voltage is zero. Note that this could take more than an hour. Once the voltage is zero, the powerbank has been fully depleted. Take note of value displayed under "Capacity". The value is given in mAh (milliamp hours). As an example, a capacity value of 2000mAh produced with a current of 1000mA would indicate that the powerbank delivered for a total of 2 hours, and a capacity value of 2250mAh produced with a current of 1500mA would indicate that the powerbank delivered for a total of 1.5 hours. Below is a screenshot of a measurement obtained after drawing 1000mA current from a powerbank for about 1.3 hours. The capacity reads 1288mAh.

Is calibration required?

- The unit should provide accurate measurements out of the box, with its default calibration. Typical default accuracy is around 1% for voltage readings and ±10mA for current measurement. So, for most uses, further calibration is not required. However, experienced users with suitable 3rd party equipment can calibrate the PM125 testers to improve the voltage and current measurement accuracy. PM110 devices can not be calibrated by the user and should be returned to factory for calibration.

Can I test USB Type-C cables using the USB Power Delivery Tester?

- Yes, using the USB Power Delivery Tester in conjunction with a Passmark USB3 loopback plug, you can test USB Type-C cables to check the quoted current, voltage drop and data integrity over the cable.

-

Tools needed:

- A USB Power Delivery Tester

- USB3 loopback plug

- A desktop computer with a USB Type-C port (PD support). The current rating of the Type-C port should be higher than the current capability of the cable being tested.

-

Set up the test environment

- Power up the USB Power Deliver Tester by connecting the analysis port to the computer

- Attach a USB3 loopback plug to the loopback port of the USB Power Delivery tester

- Run the USBPDTest application

- Enable the loopback port from the Configuration window

- Make sure Current Limit is set to "Enforce Limits"

- Run the USB30Test application

- Select loopback testing and enable the "Check Bus Error" option from the configuration window

-

How to test a cable

Test the Power Delivery communication

- Connect the USB host port to the "the Device Under Test" port using the USB Type-C cable that need to be tested. If the "Rotate Connector" message appeared on the tester's LCD, flip the cable from where it is attached to the "Device Under Test" port.

- Check the advertised profiles in the log window. You should be able to see all the port power profiles with the current level equal or less than the cable current rating.

-

Check the maximum voltage drop

- Find the voltage level that corresponds to the highest available current and select it from the "Voltage" drop down list

- Wait for "Port capability changed" message to appear in the log window. This means that the PD communication has been successful and the new profile is selected and provided by the port.

- Move the slider to the maximum current and check the voltage to make sure the voltage remains within the specification. If voltage goes outside the valid range, a log line with red color will appear.

-

Check data integrity

- On the USB30Test application, click on the "Start" button and monitor the log window to make sure the communication is error-free. The test should run at least for 10 seconds and at the end of the loopback test no error should be reported.

Can USB chargers/ports be tested in an automated fashion using the Passmark USB Power Delivery Tester?

- Yes, we have an example Python script that does automated testing on a list of user selected profiles. The script selects the profiles one by one and performs voltage test across different loads and will prompt the user if voltage is outside the specification. It also gives an overall pass/fail at the end of the test.

Is the device suitable for high volume testing?

- The USB-C connector is small and fragile. This is the case for all devices with a USB-C connector. The connector is not designed for a high volume of cable insertions and removals such that might occur in a production line environment. Eventually the pins wear an start to make intermittent electrical contact. Twisting or too much insertion force on the connector can also result in it becoming loose and failing.

- If production line testing is required (e.g. 100s of insertions and removals per day) we suggest using an additional “disposable” extension cable that can remain permanently connected to the USB-PD tester. Once the connector on the disposable cable inevitably fails it can be replaced at low cost.

What are the best practices when using USB Type-C ports?

-

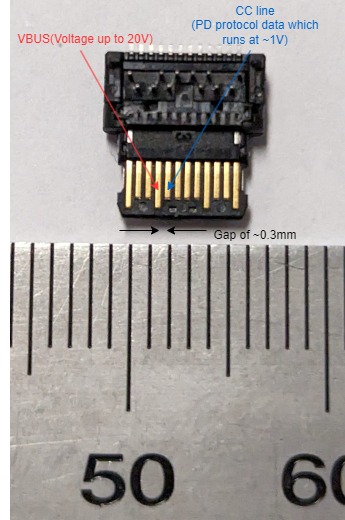

USB Type-C ports are made up of 24 small pins that are spaced 0.5mm apart from each other. This design makes the connector very fragile, as well as increasing the chance that two pins get shorted together. To avoid damaging the USB Type-C port, we recommend the following when attaching and detaching any device to the USB Power Delivery Tester.

- Insert and remove the cable as straight as possible.

- Never detach the cable when more than 5V is selected. A short between two pins is more likely in this case and can cause damage.

- Don’t insert the cable with more force than is required.

- Leave one side of the cable always inserted in the USB Power Delivery Tester and only attach / detach test devices from other side of the cable.

- Avoid wriggling or vibrating the cable when in use.

My firmware update keeps failing. Stuck on “Updating firmware… Do not unplug!” message?

- If the “Updating firmware… Do not unplug!” message has appeared on the USB Power Delivery Tester, and after several attempts to update the firmware the message continues to appear, then this means the Type-C Port Controller chip is damaged. The USB Power Delivery Tester cannot function without this chip, and the most likely cause of this failure is due to the CC pin being shorted to the VBUS pin. Following the recommended actions under the FAQ “What are the best practices when using USB Type-C ports?” greatly reduces the chance of this fault happening.

What is the difference between Hardware Revision 2.0 and Hardware Revision 2.1?

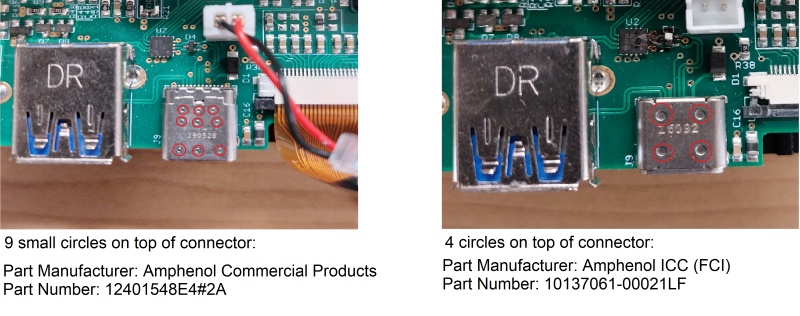

- Hardware Revision 2.0 and 2.1 are functionally identical, however, Hardware Revision 2.1 uses a different USB-C connector since the connector used on Hardware Revision 2.0 is now obsolete.

What is the part number and manufacturer of the USB-C connector?

-

The USB-C connector can be either of the two following parts depending on the USB Power Delivery Tester model:

- 12401548E4#2A by Amphenol Commercial Products

- 10137061-00021LF by Amphenol ICC (FCI)

To know which of these connectors is the one used in your USB Power Delivery Tester, compare the shape of the top of the connector with the picture below. Also note that the pins on a USB-C connector have a very fine pitch, and so replacing the connector requires special equipment.

How is the ripple value measured in the real-time voltage graph?

- Ripple value is calculated using the difference between maximum and minimum voltage measured during the entire test run. We would recommend running the test several times to get the average ripple.

- Note that transients not excluded from measurements. Also make sure voltage is constant during tests.

Can a USB host device be connected to the loopback port?

- No. Connecting the loopback port to a host device with a USB type-A plug is against the USB standards and can damage the USB-PD Tester.